產(chǎn)品導(dǎo)視

Products

Products

? Packaging Products cat...

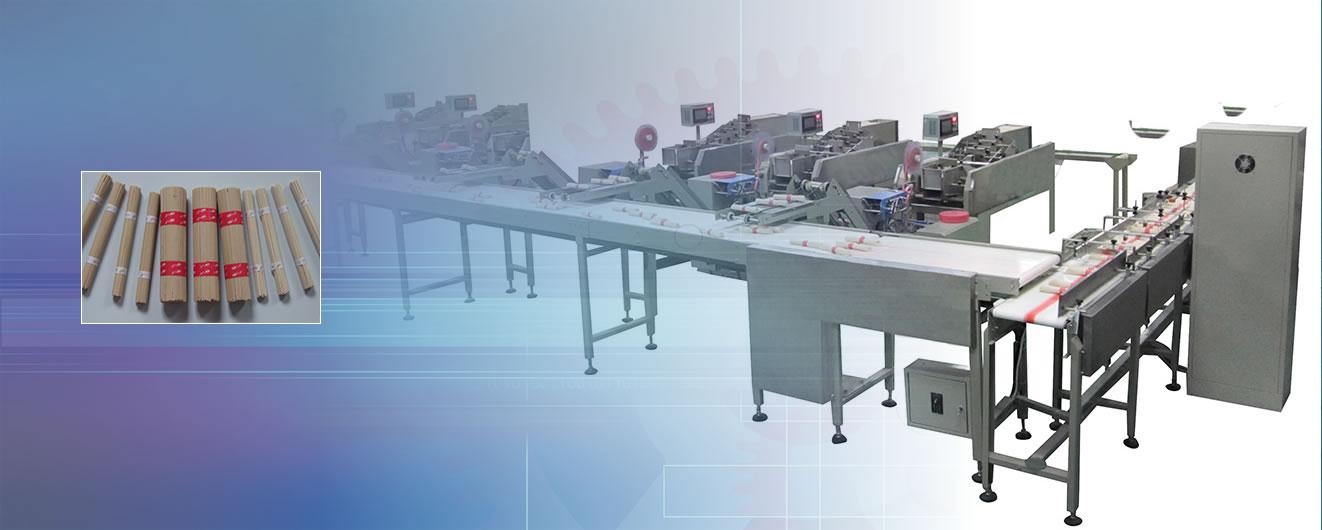

Incense sticks Packagi...

Noodle Packing Machine

Vertical Type Packing ...

Biscuit Packing Machin...

Wafer Auto Packing Mac...

Vegetable Packing Mach...

Reciprocating Type Pac...

Cup Noodle Packing Mac...

Chopsticks Packing Mac...

Seafood/Fish Packing M...

Meat/Poultry Packing M...

Ice Food Packing Machi...

Toilet Roll Packing Ma...

Bread Packing Machine

Gable Top Packing Mach...

Noodle Packing Machine

Vertical Type Packing ...

Biscuit Packing Machin...

Wafer Auto Packing Mac...

Vegetable Packing Mach...

Reciprocating Type Pac...

Cup Noodle Packing Mac...

Chopsticks Packing Mac...

Seafood/Fish Packing M...

Meat/Poultry Packing M...

Ice Food Packing Machi...

Toilet Roll Packing Ma...

Bread Packing Machine

Gable Top Packing Mach...

? Packaging Machine cate...

Down Film Packing Mach...

Shrink Wrapping Machin...

On Edge Packing Machin...

General Packing Machin...

Vertical Type Packing ...

Shrink Wrapping Machin...

On Edge Packing Machin...

General Packing Machin...

Vertical Type Packing ...

? Auto Feeding System

? Spare Parts

Company News

how to Buy packing machine

How to buy a packing machine ? what is the correct steps ? and how to avoid make serious mistakes when buy packing ?

now the steps will help you buy packing machine in shot time .

1) measure the dimensions of the products like , length ,width,height. also if needed to weigh the weight .

2) to make sure the packing material , paper or plastic (Laminated or single layer or shrink)

3) how many pcs in a bag or how much grams in a bag

4) to packing sure the sealing stype , zig or line , that need to tell our sales man .

5) also need to tell us the Length of the workshop for our packing machine

how to maintenance noodle packing machine

maintenance noodle packing machine generally good strip of material used for packing liquid. This machine is suitable for food, tea, medicine, chemical, cosmetic, metal industries such as the long strip of materials. Any machine need maintenance on a regular basis, maintenance noodle packing machine machine maintenance roughly as follows, can for your reference:

Gear lubrication

1, the box body parts of the machine is equipped with oil, should all come on at a time before driving, midway can press the bearing temperature rise and add the running status. 2, worm gear box must be long-term storage engine oil, the oil level height is worm gear all into oil, such as the frequently used, every march in new oil at a time, must be made at the bottom of the oil plug, oil can be put to use. 3,noodle packing machine the machine come on, don't make oil overflow, more do not flow into the machine and around the earth. Because oil is easy to make material pollution, affect the quality of the product.

Maintenance instructions

1, regular check parts, once a month, check the worm gear, worm, lubrication on bolts, bearings and other activities if parts flexible rotation and wear situation, found that defects should be timely repair, shall not be used. 2, the machine should be kept in dry cleaning of indoor use, shall not be in the atmosphere contain acids to the body and other corrosive gases in circulation. 3, machine after using or stops, the rotating drum should be removed in cleaning and clearing the surplus FenZi inside bucket, and then set up and prepare for next time use. 4, when the roller in the workplace happens before and after the move, please set-up M10 bolt on the front bearing stand to the appropriate location. If gear shaft moving, please set-up M10 behind bracket screws noodle packing machineto the appropriate location, adjust the clearance for bearing noise does not occur, hand belt pulley, elastic proper advisable, too tight or too loose to make damage the machine. 5, such as stop using for a long time, had to wipe and clean the body of machine, parts of smooth surface coated with anti-rust oil, canopy cover with cloth.

Machine need maintenance maintenance, hang a bread machine operation personnel should be the correct use of machines in use process, regular cleaning

now the steps will help you buy packing machine in shot time .

1) measure the dimensions of the products like , length ,width,height. also if needed to weigh the weight .

2) to make sure the packing material , paper or plastic (Laminated or single layer or shrink)

3) how many pcs in a bag or how much grams in a bag

4) to packing sure the sealing stype , zig or line , that need to tell our sales man .

5) also need to tell us the Length of the workshop for our packing machine

how to maintenance noodle packing machine

maintenance noodle packing machine generally good strip of material used for packing liquid. This machine is suitable for food, tea, medicine, chemical, cosmetic, metal industries such as the long strip of materials. Any machine need maintenance on a regular basis, maintenance noodle packing machine machine maintenance roughly as follows, can for your reference:

Gear lubrication

1, the box body parts of the machine is equipped with oil, should all come on at a time before driving, midway can press the bearing temperature rise and add the running status. 2, worm gear box must be long-term storage engine oil, the oil level height is worm gear all into oil, such as the frequently used, every march in new oil at a time, must be made at the bottom of the oil plug, oil can be put to use. 3,noodle packing machine the machine come on, don't make oil overflow, more do not flow into the machine and around the earth. Because oil is easy to make material pollution, affect the quality of the product.

Maintenance instructions

1, regular check parts, once a month, check the worm gear, worm, lubrication on bolts, bearings and other activities if parts flexible rotation and wear situation, found that defects should be timely repair, shall not be used. 2, the machine should be kept in dry cleaning of indoor use, shall not be in the atmosphere contain acids to the body and other corrosive gases in circulation. 3, machine after using or stops, the rotating drum should be removed in cleaning and clearing the surplus FenZi inside bucket, and then set up and prepare for next time use. 4, when the roller in the workplace happens before and after the move, please set-up M10 bolt on the front bearing stand to the appropriate location. If gear shaft moving, please set-up M10 behind bracket screws noodle packing machineto the appropriate location, adjust the clearance for bearing noise does not occur, hand belt pulley, elastic proper advisable, too tight or too loose to make damage the machine. 5, such as stop using for a long time, had to wipe and clean the body of machine, parts of smooth surface coated with anti-rust oil, canopy cover with cloth.

Machine need maintenance maintenance, hang a bread machine operation personnel should be the correct use of machines in use process, regular cleaning