產(chǎn)品導(dǎo)視

Products

Products

? Packaging Products cat...

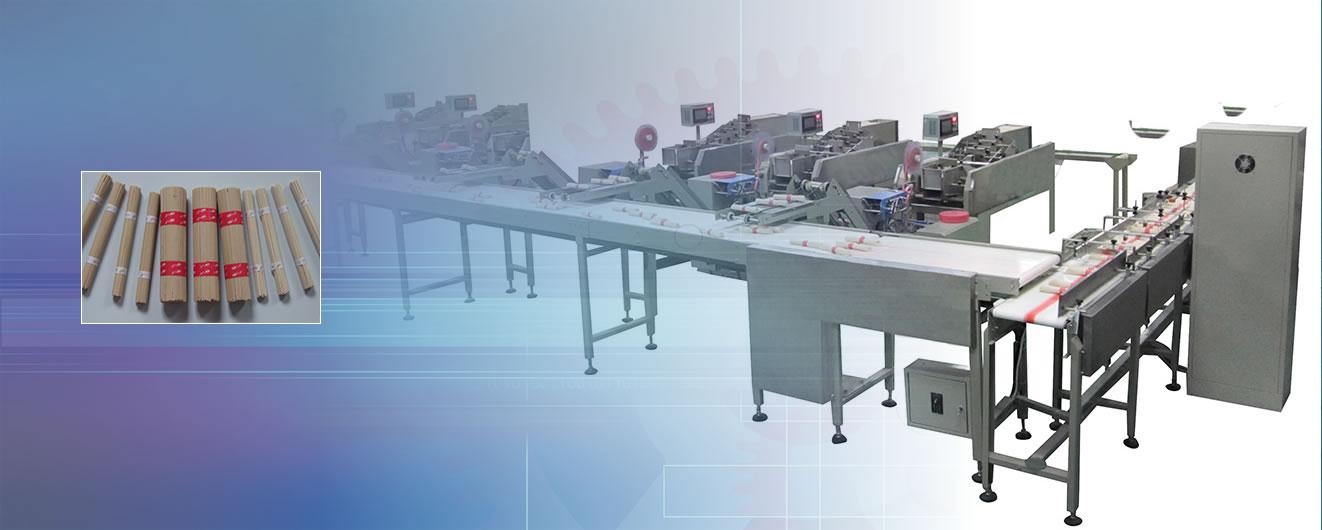

Incense sticks Packagi...

Noodle Packing Machine

Vertical Type Packing ...

Biscuit Packing Machin...

Wafer Auto Packing Mac...

Vegetable Packing Mach...

Reciprocating Type Pac...

Cup Noodle Packing Mac...

Chopsticks Packing Mac...

Seafood/Fish Packing M...

Meat/Poultry Packing M...

Ice Food Packing Machi...

Toilet Roll Packing Ma...

Bread Packing Machine

Gable Top Packing Mach...

Noodle Packing Machine

Vertical Type Packing ...

Biscuit Packing Machin...

Wafer Auto Packing Mac...

Vegetable Packing Mach...

Reciprocating Type Pac...

Cup Noodle Packing Mac...

Chopsticks Packing Mac...

Seafood/Fish Packing M...

Meat/Poultry Packing M...

Ice Food Packing Machi...

Toilet Roll Packing Ma...

Bread Packing Machine

Gable Top Packing Mach...

? Packaging Machine cate...

Down Film Packing Mach...

Shrink Wrapping Machin...

On Edge Packing Machin...

General Packing Machin...

Vertical Type Packing ...

Shrink Wrapping Machin...

On Edge Packing Machin...

General Packing Machin...

Vertical Type Packing ...

? Auto Feeding System

? Spare Parts

Company News

How to install packing machine

Operating instructions

(1) Precautions:

1) Before operations, please read carefully this operating instructions manual.

In case of any faults, please consult professional technicians or notify the manufacturer.

2) This machine adopts AC 3-phase 380V, 50Hz power source.

Make sure the machine has been earthed reliably before turning it on.

(2) How to operate:

1) Position the main power switch, the power indicator is lit on (in red).

2) Turn the main machine operating knob (MAIN) to ON, the RUN indicator is lit on. Then, the main transmission belt of the thermal-shrink machine starts to move, the blower fans #1 and #2 begin to work, and (FAN1) and (FAN2) indicators are lit. The temperature controller display the set temperature and actual temperature. You may set a temperature as you desire.

3) Turn the knobs of heater (HEATER1), (HEATER2) to “ON”, heaters 1# and 2# start to heat up, until the set temperature is reached.

4) Put the packaged items subjected to shrinkage on the meshy belt of the thermal-shrink machine, and push it into the machine for shrinkage. Observe the shrinkage effects after taking it out of the machine. If the effects are not satisfactory, you may adjust the flow speed of the belt and the heating temperature, then re-rest, until your desired effects turn out.

(Notes: the shrinkage effects differ from various parameters of the films and requirements of clients on the flow speed of the meshy belt).

5) When turning off the machine, be sure to turn the knobs of heaters #1 & #2 (HEATER1) and (HEATER2) to “OFF”, to stop the working of heaters #1 and #2. At that time, the actual temperature displayed by the temperature controller begins to fall down. Until the displayed temperature value reached under 50°C, you may then turn the “MAIN” knob to “OFF” position, to let the main machine and blower fans #! And #2 stop working.

(★important: otherwise, the main transmission belt may get deformed due to too high a temperature inside the machine, which may affect the working performance of the machine).

6) When blower fans #1 and #2 are overloaded, “FAN1OL” and “FAN2OL” indicators will be lit accordingly, showing that the blower fan #1 or #2 is overloaded.

(1) Precautions:

1) Before operations, please read carefully this operating instructions manual.

In case of any faults, please consult professional technicians or notify the manufacturer.

2) This machine adopts AC 3-phase 380V, 50Hz power source.

Make sure the machine has been earthed reliably before turning it on.

(2) How to operate:

1) Position the main power switch, the power indicator is lit on (in red).

2) Turn the main machine operating knob (MAIN) to ON, the RUN indicator is lit on. Then, the main transmission belt of the thermal-shrink machine starts to move, the blower fans #1 and #2 begin to work, and (FAN1) and (FAN2) indicators are lit. The temperature controller display the set temperature and actual temperature. You may set a temperature as you desire.

3) Turn the knobs of heater (HEATER1), (HEATER2) to “ON”, heaters 1# and 2# start to heat up, until the set temperature is reached.

4) Put the packaged items subjected to shrinkage on the meshy belt of the thermal-shrink machine, and push it into the machine for shrinkage. Observe the shrinkage effects after taking it out of the machine. If the effects are not satisfactory, you may adjust the flow speed of the belt and the heating temperature, then re-rest, until your desired effects turn out.

(Notes: the shrinkage effects differ from various parameters of the films and requirements of clients on the flow speed of the meshy belt).

5) When turning off the machine, be sure to turn the knobs of heaters #1 & #2 (HEATER1) and (HEATER2) to “OFF”, to stop the working of heaters #1 and #2. At that time, the actual temperature displayed by the temperature controller begins to fall down. Until the displayed temperature value reached under 50°C, you may then turn the “MAIN” knob to “OFF” position, to let the main machine and blower fans #! And #2 stop working.

(★important: otherwise, the main transmission belt may get deformed due to too high a temperature inside the machine, which may affect the working performance of the machine).

6) When blower fans #1 and #2 are overloaded, “FAN1OL” and “FAN2OL” indicators will be lit accordingly, showing that the blower fan #1 or #2 is overloaded.