Products

Noodle Packing Machine

Vertical Type Packing ...

Biscuit Packing Machin...

Wafer Auto Packing Mac...

Vegetable Packing Mach...

Reciprocating Type Pac...

Cup Noodle Packing Mac...

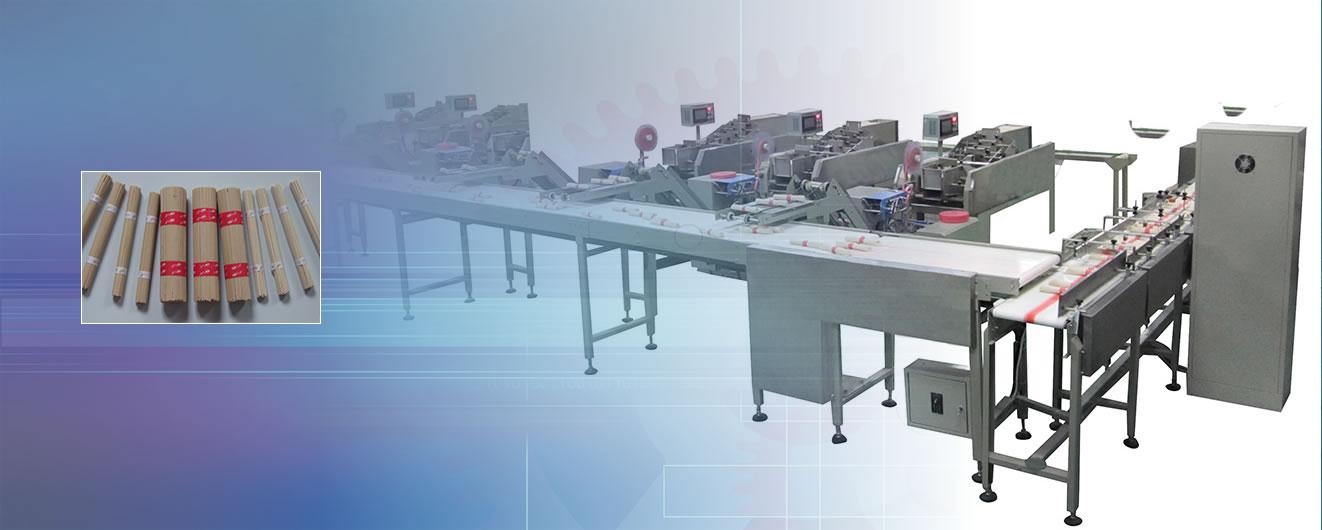

Chopsticks Packing Mac...

Seafood/Fish Packing M...

Meat/Poultry Packing M...

Ice Food Packing Machi...

Toilet Roll Packing Ma...

Bread Packing Machine

Gable Top Packing Mach...

Shrink Wrapping Machin...

On Edge Packing Machin...

General Packing Machin...

Vertical Type Packing ...

Screws/Nails/bolts/Small parts Packing Machine

Automatic Packing Machine Specification:

APPLICATIONS:

Suitable for automatic packaging of screws ,nuts, bolts, nails, small parts and consumer goods, etc.

Screw packing machine features

1, using PLC touch screen control system, support Chinese and English, simple and practical operation.

2. Optional thermal transfer printer prints QR code, barcode, batch number and other information on the packaging film.

3. The vibrating plate runs smoothly, has low noise, does not damage the raw materials, and adopts precise counting control device to ensure the accuracy of counting.

4. Each set of vibrating plate is equipped with full stop, material shortage alarm or stop device to ensure that each bag is accurate. The device has a self-diagnostic function.

When there is a fault, it can automatically alarm or stop (the alarm or stop user can choose), and there are multiple emergency stop buttons for easy operation.

5, the equipment can achieve automatic material sorting, automatic counting, filling, sealing, packaging, conveying, sorting, and. The number of products can be adjusted freely, the number of bags can be controlled by themselves, and the number of packages can be automatically displayed, which can conveniently count the workload of the machine.

6, highly compatible, can meet the packaging requirements of more than 90% of the different shapes of the market.

7. A chain track is installed in the chain bucket. The chain is more stable, fast, safe and low in noise.

8. This machine has no material and no material to be automatically detected. When there is no material or no material, the equipment will automatically stop the alarm. Each feeder in the equipment can be free.

Turn it on or off.

9. High working efficiency,

according to the speed of materials, the speed can reach 30 to 60 packs/min,

saving more than 80% of labor, and the feeding speed of single station can

reach 400 pieces/min. (The specific packaging speed is determined by factors

such as material shape and technology)

Technical parameter:

|

Model |

M8-300B |

|

|

Roll Max. Width in mm |

300MM |

|

|

Max Bag Size |

140*190MM(Bag Size as Requirments) |

|

|

Types of Packaging Composite Film |

Packaging Composite Film, PE/Paper, OPP/PE, ALU/PE and etc |

|

|

Power Required |

220V/AC, 1 phase, 50 Hz 3.66 KW |

|

|

Machine Weight KG |

600kgs |

|

|

Speed |

30 to 60 packs/min |

|

|

Overall Dimension |

2800*1200*1550MM |

|

|

Bag Shape |

Back Seal Type

|

|